- Civil Lab Mechanical Lab Engineering Lab Equipments

- sales@didacticlabequipments.com

CAT NO: DIDACTICNLE-Export-210025

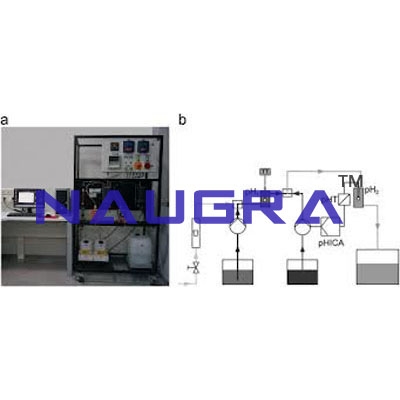

PH - Value Control Trainer- Engineering Lab Training Systems.

Technical Description

This teaching and training system

provides a comprehensive experimental introduction to the fundamentals

of process control using an example of continuous pH control.

A

caustic solution is added to fresh water by way of a metering pump. The

pH-value of this solution is measured. The acid is then added to the

solution as a neutralising reagent by way of a second metering pump. The

chemical reaction occurs in a pipeline system. The pH-value is then

remeasured. A state-of-the-art digital industrial controller controls

the second metering pump with reference to this pH-value. The

neutralised solution flows into the product tank. A third manual

measurement of the pH-value in the product tank permits disposal of

solution with a neutral pH-value. The pH-value of the input solution can

be varied by manually adjusting the metering pump or by varying the

quantity of fresh water. This enables disturbances to be simulated. The

controlled variable X and the manipulating variable Y are plotted

directly on an integrated 2-channel line recorder. Alternatively, the

variables can be tapped as analogue signals at lab jacks on the switch

cabinet. This enables external recording equipment, such as an

oscilloscope or a flatbed plotter, to be connected.

A process

control software is optionally available. The software permits the

construction of a complete networked system comprising multiple trainers

from the series. The key process variables can also be represented, and

control functions executed.

The well-structured instructional

material outlines the technological fundamentals and provides a

step-by-step guide through the experiments.