- Civil Lab Mechanical Lab Engineering Lab Equipments

- sales@didacticlabequipments.com

CAT NO: DIDACTICNLE-Export-059008

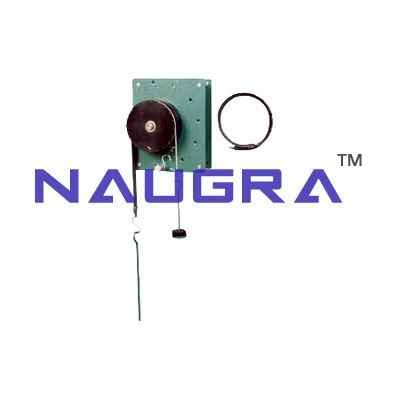

Friction of Belts Apparatus- Engineering Lab Training Systems.

Features

Low-cost effective teaching.

Self-contained.

Wall mounted.

Variable angle of lap.

Flat, round and vee belts.

Determination of coefficient of friction.

Verification of belt tension law.

Three year warranty.

Range of Experiments

To observe the relationship between the tensions in the two sides of a belt

To assess the differences between Vee, rope, and flat belts

To determine the coefficient of friction between the pulley and belt for the belt sections

To investigate the effect of angle of lap

Description

The

apparatus consists of a wall mounted pulley with a loaded belt. The

pulley is made of aluminum and has two machined grooves to suit a flat

Vee belt, and a rope.

For a given belt tension and angle of lap, a

turning moment can be applied by adding weights to the pulley drive

hanger. The idea is to determine the torque which just causes the pulley

to turn, and so to find the ratio of the belt tensions. This enables

the belt tension equation to be verified and the coefficient of friction

to be determined.

The angle of lap can be easily varied.

This

equipment is part of a range designed to both demonstrate and

experimentally confirm basic engineering principles. Great care has been

given to each item so as to provide wide experimental scope without

unduly complicating or compromising the design. Each piece of apparatus

is self-contained and compact. Setting up time is minimal, and all

measurements are made with the simplest possible instrumentation, so

that the student involvement is purely with the engineering principles

being taught. A complete instruction manual is provided describing the

apparatus, its application, experimental procedure and typical test

results.